Links

| Please donate if you find this site useful. |

| Fay Marine |

| Yacht Plans |

| Anchors & Anchoring |

| Batteries |

| Battery Desulphation |

| Diesel Fuel |

| Electricity |

| Engines |

| Free Fire Design |

|

|

|

|

Holding tank

It is becoming increasingly necessary for yachts and motor boats to have a black water holding tank. Black water is what is pumped out of the toilet and grey water is everything else such as water from washing up dishes and showering.

Almost all areas of closed water such as marinas that have to be locked into, many rivers and the coastal waters of some countries demand that there is no black water discharged into these waters. In fact in many places it is becoming illegal to discharge ‘black’ water from your boat and if caught by the authorities discharging can result in a hefty fine. It is also not very nice when in an anchorage where crews want to swim and snorkel to discharge overboard during the day.

Many years ago when we first visited the USA we came across the problem of needing a holding tank. I approached a small company who specialised in this type of thing and took their advice. They then supplied us with a small simple tank the design of which we have slowly modified over the years to make it work well.

This design can be fitted in a locker close to the heads above the waterline and will provide a few days storage if you don’t use it to excess.

There are no moving parts apart from the valves which are hand operated. No electric or manual pump is necessary as the whole system relies on gravity to drain it.

Inevitably all tanks will block at some point and will need a method of unblocking. It is nearly always the outlet which blocks and so a simple method of unblocking the drain tube has been designed.

Easy unblocking has been achieved by lining up the pump out part / tube with the drain tube so that the system can be ‘rodded’ from the deck.

The design.

A box is made that will fit into a locker as close to the head as possible. We have one that will hold 40 gallons but in reality for a small yacht the 20 gallon tank that we first used is adequate.

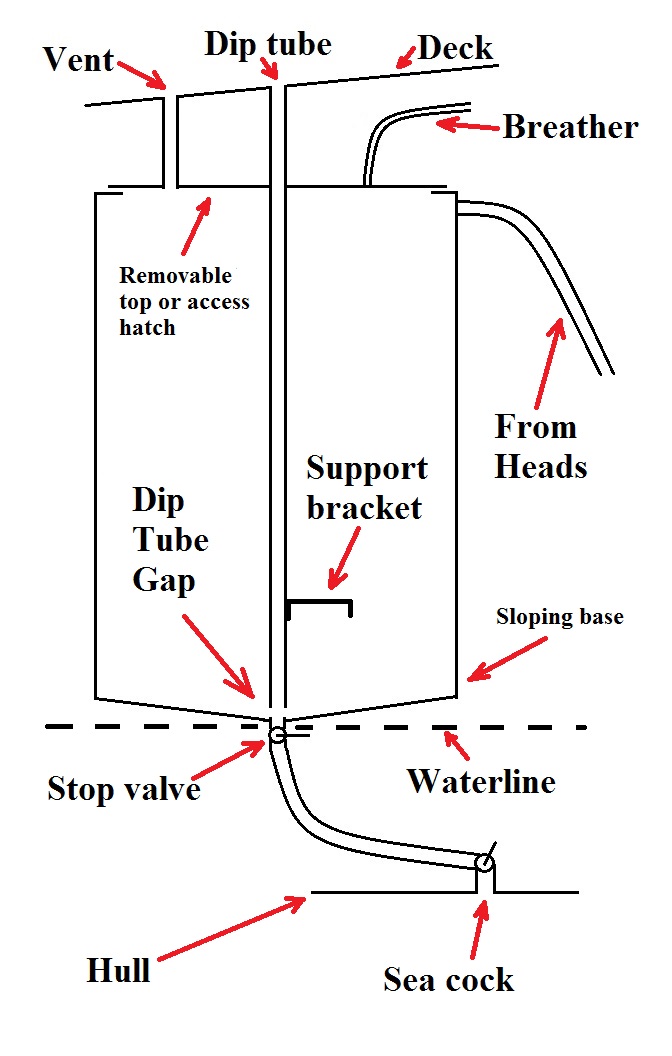

The box can be virtually any shape to fit the boat but it is best if the box is tall rather than squat. This makes draining easier. A 2 inch tube is fitted to the bottom of the box which will drain down to a sea cock. The bottom of the box should gently slope towards this outlet tube to aid draining. It is best if this tube is 2 inches rather than the 1.5 inch normal heads tubing. We originally had the smaller tube but found that it blocked too easily so changed it to the larger tube and sea cock.

The bottom of the box needs to be slightly above the ‘at rest’ waterline. This ensures proper draining and also when the boat is sailing through waves the wave action will wash out the bottom of the tank.

The sea cock can be used as the stop valve but as this allows the tube to fill with solids which may solidify and then not easily drain, so it is best to fit a stop valve at the tank.

The heads pumps into the top of the box and normal 1.5 inch tube is fine for this. This tube can either be fitted into the top or the side as close to the top as possible.

The top of the box can either be completely removable or have an access hatch. A fixed top should not be used as it may be necessary to gain access and to ensure that the pump out tube can be properly supported and aligned.

In the top of the box there are 3 tube fittings. One is an air vent which can be ˝ inch tube which vents through the side of the boat. It is best if no valve is fitted to this air vent as if it is closed when the tank is being used the internal pressure could easily cause the tank to burst. One is a wash out which doubles as an inlet vent when pumping out and needs to be 1.5 inch tube. This needs to be the same size as the pump out to stop a vacuum in the tank during pump out which could collapse the tank. The third is the pump out which needs to be 1.5 inch tube and fittings.

The pump out needs a dip tube inside the box which goes almost to the bottom of the tank. The gap between the lower end of this tube and the bottom of the tank needs to be 1.5 inches. The dip tube and deck fittings will be 1.5 inch which will fit the pump out facilities provided in marinas and canals.

As is shown in the drawing this internal tube needs to align with the drain tube. Also the flexible tube going to the deck pump out fitting needs to be as straight as possible as it goes up to the deck to allow the whole system to be ‘rodded’ through. If this all lines up well, then when the inevitable blockage occurs, a reasonably flexible length of plastic or a flexible sink rod can be used to rod all the way through to the sea cock. This pushes the blockage out and allows the system to drain.

As the internal tube passes from the top of the tank almost to the bottom the lower end of this tube needs support to keep it aligned with the drain tube. This is because when ‘rodding’ the system sideways force can be applied at the bottom of the tube misaligning it with the drain tube and perhaps even breaking it.

This type of holding tank removes the need for a vented swan neck in the outlet as the breather stops the system being able to siphon. An anti siphon is still needed on the inlet.

If putting paper through then the paper that is used in the heads must be the type that will quickly disintegrate in water. I would test different makes of paper by putting it in a jar full of water giving it a shake to ensure that it disintegrated easily. Then the manufacturer of the paper we were using must have changed the formula as the tank blocked and when I removed the tank top I found the tank full of paper. After that like many boats we stopped putting paper through the head, providing a container in the heads in which to put it. Since doing that we have had very few problems. Anyway we always found that the type of paper that disintegrates is very unsatisfactory to use.

Having refined it we have been using this design for over 10 years and have found that it works well. The only maintenance that we have had to carry out is to regularly treat the whole system with hydrochloric acid to remove the calcium build up and regularly grease the head pump.